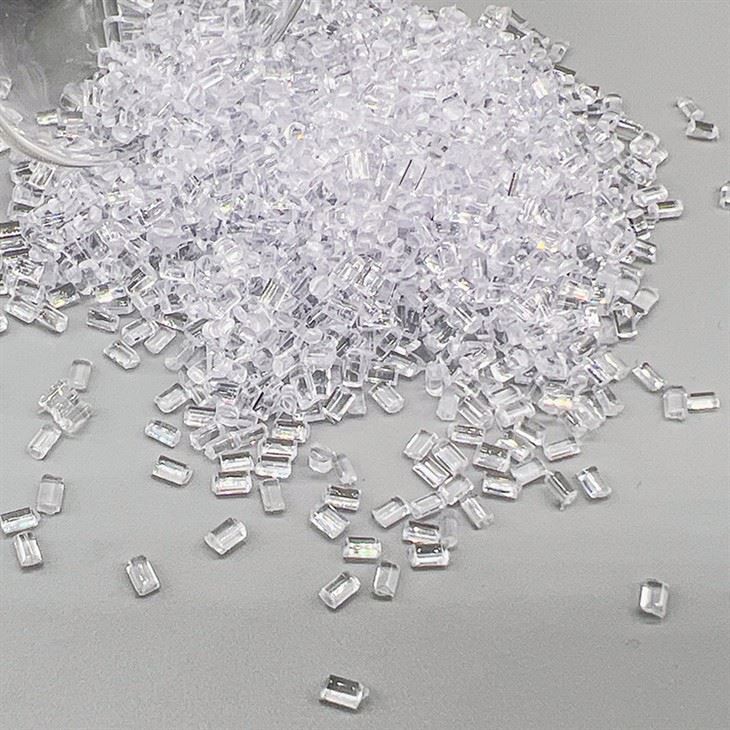

| Stretch film grade resin |

LLDPE Plastic Granules (LLDPE) is a molecular structure with very short copolymerization of ethylene with a small amount of α -olefin on the main chain of linear ethylene.

LLDPE Plastic Granules is non-toxic, tasteless, odorless milky particles, the density of 0.918~0.935g/cm3. It compared with LDPE, have high softening temperature and melt temperature, has good strength and toughness, rigidity, heat, cold resistance is good wait for an advantage, but also has good envi resistanceronmental stress cracking resistance, resistance to impact strength, tear strength and other properties, and acid, alkali, organic solvent and widely used in industry, agriculture, medicine, health and daily life supplies, and other fields.

LLDPE Plastic Granules for Films: The Top Choice for Flexible Packaging

When it comes to flexible packaging, LLDPE plastic granules are the top choice for a variety of reasons. LLDPE stands for linear low-density polyethylene, which is a type of plastic that offers a unique combination of properties that make it ideal for films used in the packaging industry.

One of the key features of LLDPE plastic granules is their excellent flexibility. LLDPE films are incredibly stretchable and elastic, which means they can conform to the shape of the product they are packaging without tearing or breaking. This makes LLDPE films perfect for wrapping products that have irregular shapes, such as food items or pharmaceuticals.

In addition to their excellent flexibility, LLDPE plastic granules also offer excellent puncture resistance. This means that they can withstand the rigors of transportation and handling without getting damaged, which helps to ensure that the product inside remains safe and protected. This is especially important for packaging items that are fragile or easily damaged.

Another advantage of LLDPE plastic granules is their ability to be manufactured in a range of thicknesses and densities. This means that they can be tailored to the specific needs of the product they are packaging. For example, thin LLDPE films can be used to wrap food items, while thicker films can be used for heavy-duty industrial applications.

LLDPE plastic granules are also a more environmentally friendly option than some other types of plastics. They can be recycled and reused multiple times, which reduces waste and the need for new plastics to be produced. This is an important consideration for companies that are focused on sustainability and reducing their environmental impact.

Overall, LLDPE plastic granules are a superior choice for flexible packaging films. They offer excellent flexibility, puncture resistance, and variability in thickness, while also being environmentally friendly. If you're looking for a reliable packaging solution for your products, LLDPE plastic granules are definitely worth considering.

Hot Tags: lldpe plastic granules for films, China lldpe plastic granules for films manufacturers, suppliers, factory, LLDPE Virgin Plastic Granules, titanium dioxide in lotion, 10 oz non woven geotextile fabric, 8 oz nonwoven geotextile, recycled pp, polyester needle punched nonwoven fabric